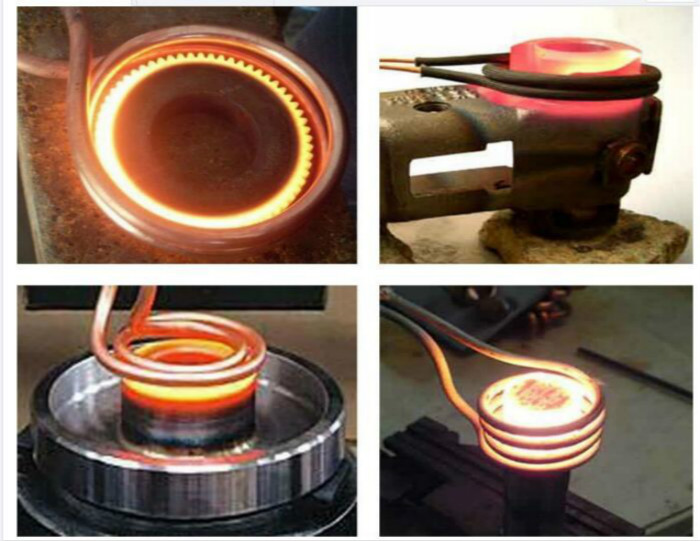

60KW/100-400KHZ gear induction hardening machine

- super high frequency induction heating machine ,hardening depth can be low at 0.5mm

Features

1. SHF series have higu frequency, able to heating material of φ 0.1mm.

2. MOSFET technology based and high frequency.

3. Easy to install and operate. Do not need any basis to work.

4. 100% duty cycle, 24 hours no-stop melting ability, energy saving and environmental protection.

5. Small size and light weight,

6. Easy and safe to use: All-round indicator lights controller, much safer and easier to operate.

Technical parameters

Models | Maximum input power | Oscillating frequency | Maximum input current | Input voltage | Duty cycle |

SHF-04A | 4KW | 100-250KHZ | 15A | Single phase 220V | 80% |

SHF-05AB | 5KW | 0.5-1.1MHZ | 15A | Single phase 220V | 80% |

SHF-06A-I | 6.6KW | 200-500KHZ | 30A | Single phase 220V | 80% |

SHF-06A-II | 6KW | 200-700KHZ |

SHF-06A/AB-III | 10KW | 0.5-1.1MHZ |

SHF-10A | 20KW | 50-300KHZ | 15A | 3phase 380V | 100% |

SHF-20AB | 20KW | 50-250KHZ | 30A | 3phase 380V | 100% |

SHF-30AB | 30KW | 50-200KHZ | 45A | 3phase 380V | 100% |

SHF-40AB | 40KW | 50-200KHZ | 60A | 3phase 80V | 100% |

SHF-60AB | 60KW | 30-150KHZ | 90A | 3phase 380V | 100% |

SHF-100AB | 100KW | 30-150KHZ | 150A | 3phase 380V | 100% |

SHF-160AB | 160KW | 30-120KHZ | 240A | 3phase 380V | 100% |

This product is most suitable for many heating purposes, such as:

(1) quenching of gears and shafts.

(2) motor stator or rotor heating and thermal cooperation.

(3) tableware heating and hot pressing.

(4) standard parts (bar copper, steel, iron, etc., with diameter of less than 35mm) are heated and formed.

35kw Bolts induction heating for forging machine

35kw Bolts induction heating for forging machine  90KW Gear shaft Heat Treatment Induction Heating Machine

90KW Gear shaft Heat Treatment Induction Heating Machine  120KW High Frequency Induction Heating Machine of Metal

120KW High Frequency Induction Heating Machine of Metal  200KW Industrial Electric Induction Heating Generator

200KW Industrial Electric Induction Heating Generator  300KW induction heating equipment

300KW induction heating equipment  160KW Electromagnetic Induction Heating Equipment

160KW Electromagnetic Induction Heating Equipment  65KW Steel bar induction heater machine

65KW Steel bar induction heater machine  Medium Frequency Induction Forging Furnace

Medium Frequency Induction Forging Furnace  100KW steel rod induction forging machine

100KW steel rod induction forging machine  160KW induction heating machine

160KW induction heating machine  200KW Bolts nuts forging induction heating furnace

200KW Bolts nuts forging induction heating furnace  400KW IGBT IF Induction Forging Furnace

400KW IGBT IF Induction Forging Furnace  400KW Steel bar threading Induction Heating Equipment

400KW Steel bar threading Induction Heating Equipment  600KW Automatic Feeding Induction Heating System

600KW Automatic Feeding Induction Heating System  All-in-one induction forging heating furnace

All-in-one induction forging heating furnace