Medium Frequency Induction Forging Furnace

- Medium Frequency Induction Forging Furnace for bolts nuts heating ,hot forging

Medium Frequency Induction Forging furnace for Bolts Nuts

Horizontal All-in-one MF induction heating furnace ,IGBT Type

Induction heating used for diathermy forging industry

1, steel plate heating, bending forming.

2, standard parts, through-heat forming of fasteners.

3, hardware tools diathermy, such as pliers, wrenches and other heating and thermoforming.

4. The tapping of the taper shank of

the prospecting rod.

5, steel pipe through thermoforming such as elbows.

Advantages

1.Adopts Germany Siemens IGBT modules, save energy 30% than traditional high frequency tube heater.

2. Protect full.Over current.over voltage,lack of phase,water shortage, etc. more than ten alarm lamps.

3. Heating fast.Within1 second ,temperature rise up to 1200 degree,even higher.

4. No need contacting work pieces, safety, safe and reliable.

5. Environmental friendly,no pollution, good for worker's health

6. Easy to change induction coils, for heating different shape of steel billet

7. Easy to install and operate.

8. Low maintenance cost

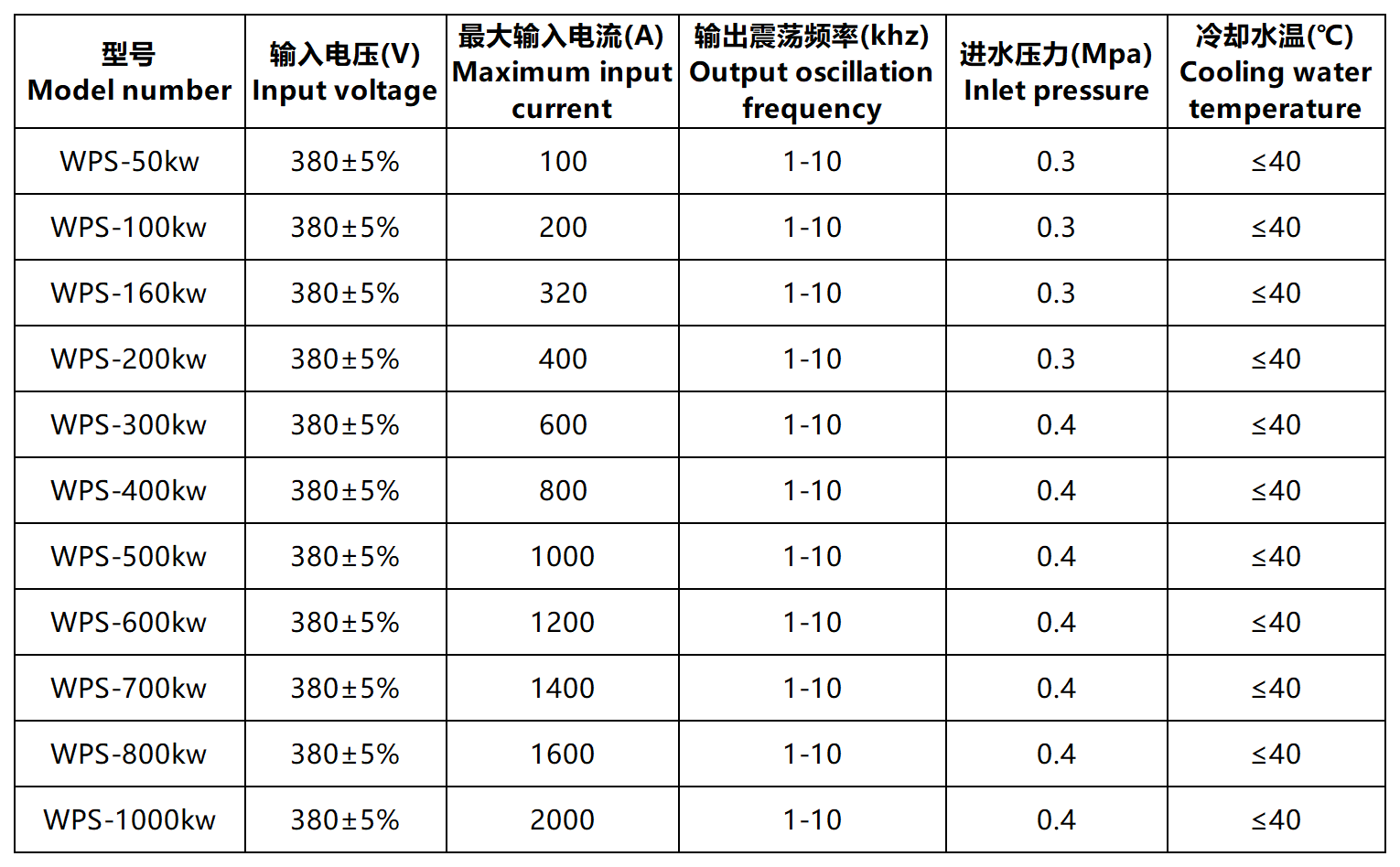

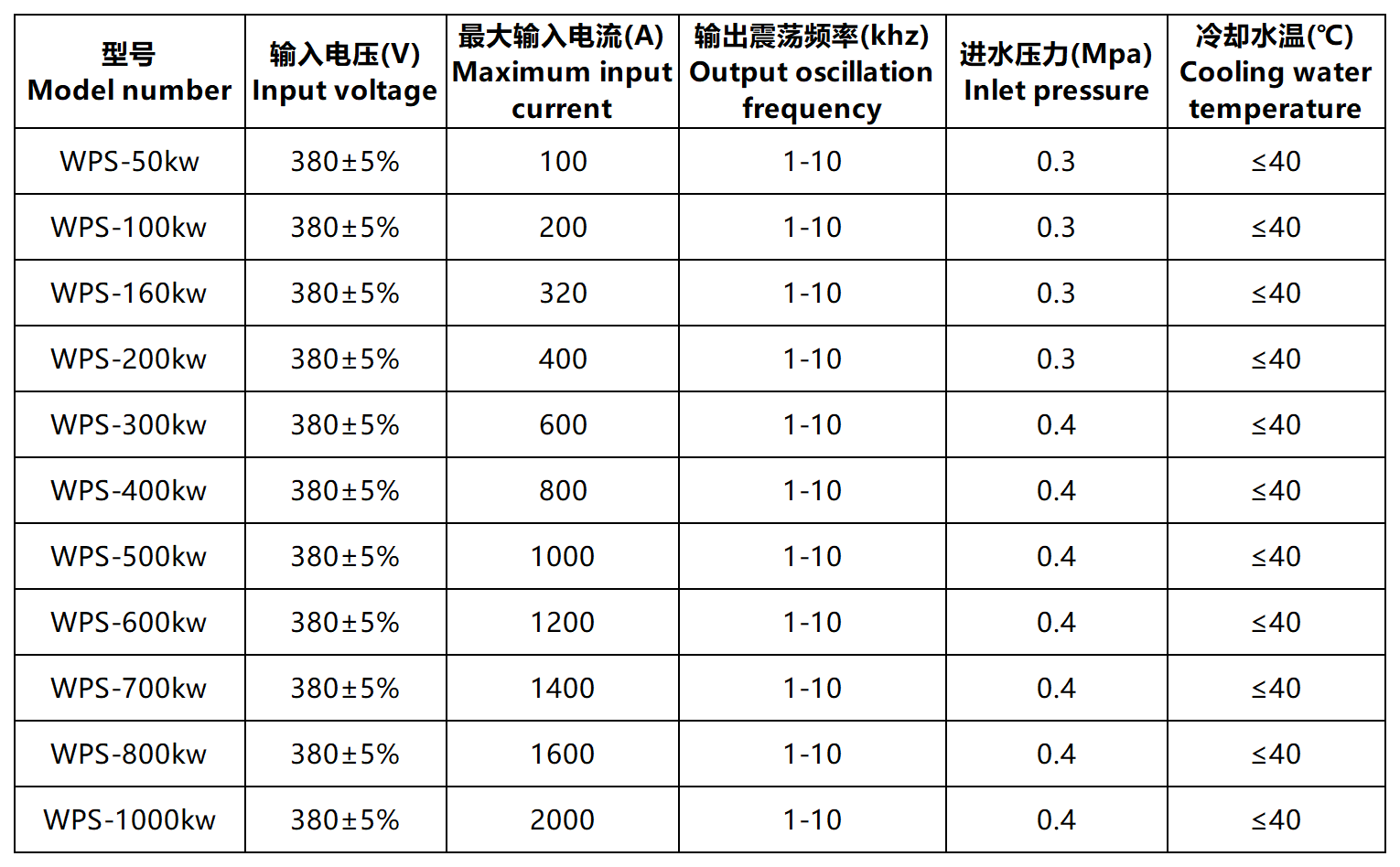

Technial parameters

| WPS-300 power range | 10-300KW |

| Oscillation Frequency | 1-10KHZ |

| Max.output current | 600A

|

| Cooling water pressure | 0.3MPA |

| Work power | 3PH 380V+/-10% |

35kw Bolts induction heating for forging machine

35kw Bolts induction heating for forging machine  90KW Gear shaft Heat Treatment Induction Heating Machine

90KW Gear shaft Heat Treatment Induction Heating Machine  120KW High Frequency Induction Heating Machine of Metal

120KW High Frequency Induction Heating Machine of Metal  200KW Industrial Electric Induction Heating Generator

200KW Industrial Electric Induction Heating Generator  300KW induction heating equipment

300KW induction heating equipment  160KW Electromagnetic Induction Heating Equipment

160KW Electromagnetic Induction Heating Equipment  65KW Steel bar induction heater machine

65KW Steel bar induction heater machine  Medium Frequency Induction Forging Furnace

Medium Frequency Induction Forging Furnace  100KW steel rod induction forging machine

100KW steel rod induction forging machine  160KW induction heating machine

160KW induction heating machine  200KW Bolts nuts forging induction heating furnace

200KW Bolts nuts forging induction heating furnace  400KW IGBT IF Induction Forging Furnace

400KW IGBT IF Induction Forging Furnace  400KW Steel bar threading Induction Heating Equipment

400KW Steel bar threading Induction Heating Equipment  600KW Automatic Feeding Induction Heating System

600KW Automatic Feeding Induction Heating System  All-in-one induction forging heating furnace

All-in-one induction forging heating furnace