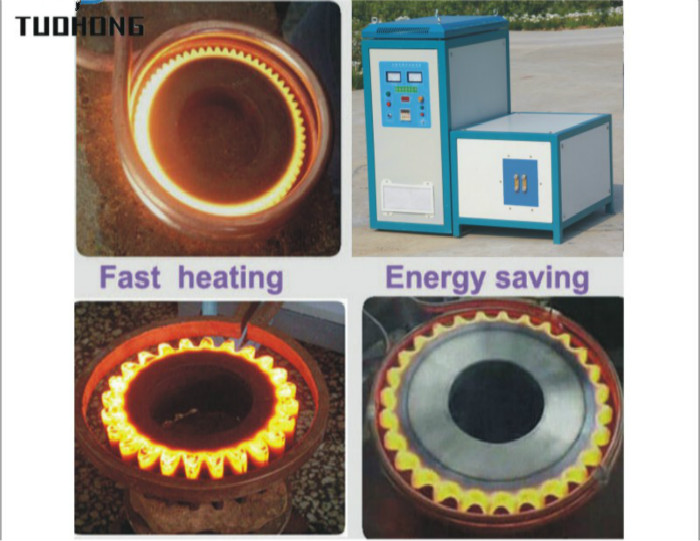

90KW Gear shaft Heat Treatment Induction Heating Machine

- high frequency induction heating machine, can be used for heat treatment gear and shaft, surface hardening/quenching

Features of igbt induction heating machine

1, my company transistor (IGBT) high frequency power-saving than vacuum tube up to 40-60%, saving 60%, external support facilities to reduce investment by 75%.

2, a unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

3, small size, light weight, easy to move, no million-volt high-voltage danger, safe operation.

4, high reliability, easy to maintain and improve the over voltage, over current, overheating, lack of, water and other self-protection.

5, use large scale integrated circuit digital automatic control, with manual, automatic, semi-automatic, and the lack of heat insulation of cold sub-time control functions.

6, automatic frequency tracking, stepless power adjustment, easy to use, 10 minutes to learn to use.

7, the company has a complete sales service system and the treatment of professional engineers, to ensure that you have no worry about technology or service.

Applications: surface hardening,quenching,heat treatment

It is mainly through the process of heating the workpiece material hardness of the metal after making changes.Specific applications are as follows:

1, various hardware tools, hand tools. Such as pliers, wrench, hammer, ax, screwdriver, scissors (gardening scissors) and the quenching;

2, Various automotive, motorcycle accessories. Such as crankshaft, connecting rod, piston pin, wheel, aluminum wheels, valves, rocker shaft, drive axle, a small shaft, fork, etc. quenching;

3, various power tools. Such as gear, shaft;

4, the machine tool industry . Such as machine tool bed, Machine Tool, etc. quenching;

5, various hardware metal parts, machining parts. Such as shaft, gear (sprocket), cam, clamps, fixtures, etc. quenching;

6, the metal mold industries. Such as small mold, die attachment, die quenching the hole, etc.;

Technical parameters of heat treatment induction heating machine

Model | Input voltage | Input current | Oscillation frequency | Cooling water pressure |

WZP-40 | 320-420V | 2-40A | 10-50KHZ | 0.1MPA |

WZP-60 | 320-420V | 3-60A | 10-50KHZ | 0.2MPA |

WZP-90 | 320-420V | 4-90A | 10-50KHZ | 0.3MPA |

WZP-120 | 320-420V | 6-120A | 10-50KHZ | 0.3MPA |

WZP-160 | 320-420V | 6-160A | 10-50KHZ | 0.3MPA |

WZP-200 | 320-420V | 6-200A | 10-50KHZ | 0.3MPA |

WZP-300 | 320-420V | 6-300A | 10-50KHZ | 0.3MPA |

WZP-400 | 320-420V | 6-400A | 8-15KHZ | 0.3MPA |

WZP-500 | 320-420V | 6-500A | 8-15KHZ | 0.3MPA |

35kw Bolts induction heating for forging machine

35kw Bolts induction heating for forging machine  90KW Gear shaft Heat Treatment Induction Heating Machine

90KW Gear shaft Heat Treatment Induction Heating Machine  120KW High Frequency Induction Heating Machine of Metal

120KW High Frequency Induction Heating Machine of Metal  200KW Industrial Electric Induction Heating Generator

200KW Industrial Electric Induction Heating Generator  300KW induction heating equipment

300KW induction heating equipment  160KW Electromagnetic Induction Heating Equipment

160KW Electromagnetic Induction Heating Equipment  65KW Steel bar induction heater machine

65KW Steel bar induction heater machine  Medium Frequency Induction Forging Furnace

Medium Frequency Induction Forging Furnace  100KW steel rod induction forging machine

100KW steel rod induction forging machine  160KW induction heating machine

160KW induction heating machine  200KW Bolts nuts forging induction heating furnace

200KW Bolts nuts forging induction heating furnace  400KW IGBT IF Induction Forging Furnace

400KW IGBT IF Induction Forging Furnace  400KW Steel bar threading Induction Heating Equipment

400KW Steel bar threading Induction Heating Equipment  600KW Automatic Feeding Induction Heating System

600KW Automatic Feeding Induction Heating System  All-in-one induction forging heating furnace

All-in-one induction forging heating furnace