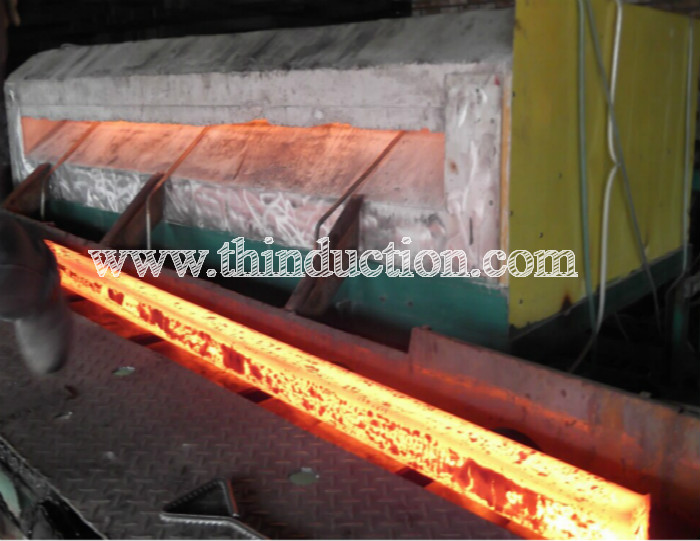

Continuous casting billets induction heating furnace

- hot billets reheating furnace, recommend to use on-line longitudinal heating.

Hot billets reheating furnace, recommend to use on-line longitudinal heating. Advantage is no need to change the walking direction of the billet,it is

matching with the continuous casting machine. Produce one piece continuous casting billet, heat one piece billet; when no continuous casting billets, Induction heating equipment can be stopped, achieve a certain energy saving effect.

We provide supporting parts of the billet reheating furnace .Transmission part with Frequency control, can change the production speed. According to our experience, it is recommended to use longitudinal heating.

Successful cases for steel billet induction heating furnace:

Continuous casting billet size: 80MM*80MM*1.5M,Heating length: 1.5M

1.1 Heating cold billets 80MM*80MM *1.5M ,Heating temperature: 1250°C

Efficiency: 60Second/Piece

1.2 Heating hot billets 80MM*80MM *1.5M

Heating temperature from 850 degree to 1250 degree ,3.5-4Ton/hour

Cold billet heating ,requires 1600 kW and heating time is 1 minute. Recommend Lateral heating. Such a scheme has the smallest footprint and more flexible production (the number of billets that can be unlimited, is used as a supplement to the caster)

1600kw steel billet heating furnace technical parameters

| Items | Parameters |

| Rated power | 1600KW |

| Incoming voltage | 660V |

| Phase | 3 |

| Rated voltage of Electric furnace | 1500V |

| Rated DC current | 1880A |

| Rated MF frequency | 1000HZ |

| Rated temperature | 1250℃ |

| Power supply specifications | KGPS-1600-1 |

Whatever size of your steel billet, just tell us your detailed requirement, we will recommend you the best suitable machine model and solution.

35kw Bolts induction heating for forging machine

35kw Bolts induction heating for forging machine  90KW Gear shaft Heat Treatment Induction Heating Machine

90KW Gear shaft Heat Treatment Induction Heating Machine  120KW High Frequency Induction Heating Machine of Metal

120KW High Frequency Induction Heating Machine of Metal  200KW Industrial Electric Induction Heating Generator

200KW Industrial Electric Induction Heating Generator  300KW induction heating equipment

300KW induction heating equipment  160KW Electromagnetic Induction Heating Equipment

160KW Electromagnetic Induction Heating Equipment  65KW Steel bar induction heater machine

65KW Steel bar induction heater machine  Medium Frequency Induction Forging Furnace

Medium Frequency Induction Forging Furnace  100KW steel rod induction forging machine

100KW steel rod induction forging machine  160KW induction heating machine

160KW induction heating machine  200KW Bolts nuts forging induction heating furnace

200KW Bolts nuts forging induction heating furnace  300KW IGBT IF Induction Forging Furnace

300KW IGBT IF Induction Forging Furnace  400KW Steel bar threading Induction Heating Equipment

400KW Steel bar threading Induction Heating Equipment  600KW Automatic Feeding Induction Heating System

600KW Automatic Feeding Induction Heating System  All-in-one induction forging heating furnace

All-in-one induction forging heating furnace